KSA Supercenter Project

In the Kingdom of Saudi Arabia (KSA), Shell & AMG Recycling and our local partner, United Company for Industry, have formed Advanced Circular Materials Company to build the worlds most cutting-edge refinery waste metals recycling facility in the world using Shell & AMG’s best available technology solutions.

Kingdom of Saudi Arabia (KSA) is becoming a globally important region for the supply and demand of vanadium, a critical material that improves the quality of infrastructure steel and a key material in certain grid-stabilization and renewable energy battery technologies.

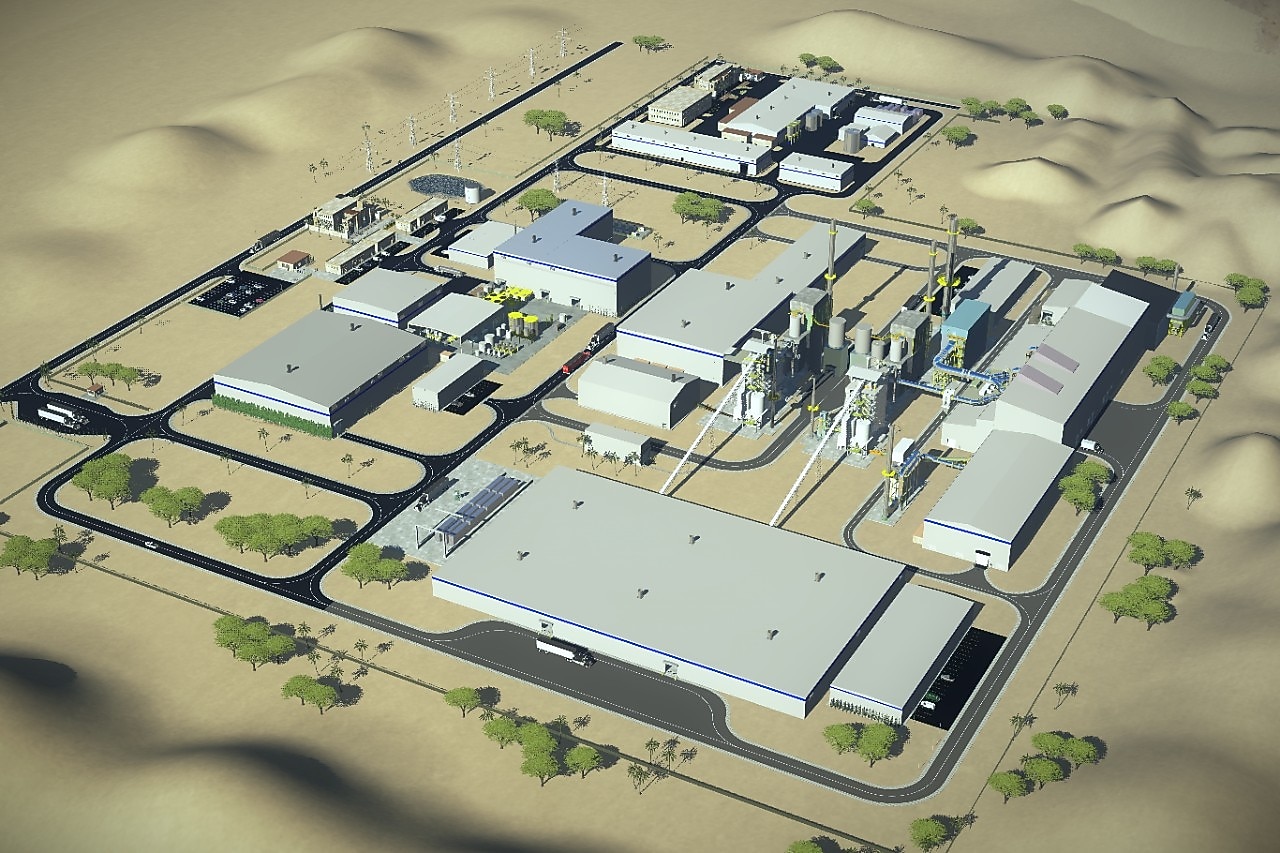

In this context, Advanced Circular Materials Company (ACMC) will construct a spent catalyst and gasification ash recycling “Supercenter” at the Jubail Industrial Complex (Plaschem Park) in the Kingdom of Saudi Arabia. This facility will turn oil refinery waste into a domestic resource to produce ferrovanadium for steel alloying and high purity vanadium oxide for use in large scale energy storage technologies. Similar ferrovanadium and vanadium oxide production facilities are currently operated by AMG in Ohio, USA and Nuremburg, Germany respectively. Technical details and experience from these reference facilities will be leveraged for this project.

The recycling supercenter will be built in phases. Phase 1 will see the construction of the process to produce battery grade vanadium oxide and vanadium electrolyte for vanadium redox flow batteries from gasification ash generated by the Jazan Refining Complex. Project Status: Detailed engineering has been kicked off and all major permits including Environmental Permit to Construct have been received, EPC contractor selection for the Execution Phase is ongoing and expected to award the contract in early Q4 2025, all long-lead equipment packages have been ordered, and vendor engineering is ongoing. Groundbreaking is planned in Q4 2025.

Phase 2 would expand the facility to process spent catalyst from heavy oil upgrading facilities in the Middle East region to produce ferrovanadium for the steel industry and/or additional battery grade vanadium oxide.

Phase 3 will be the installation of a manufacturing facility for Residue Upgrading catalysts. The manufacturing facility would seek to utilize the expertise of Shell Catalysts & Technologies that provides catalysts, technology, technical advisory services and research and development expertise to the refining and petrochemical processing industries worldwide.